Washing

Washing plays a crucial role in wet finishing since the final outcome of any pre-treatment or dyeing is hugely dependent upon how effective the washing has been.

We offer two different kinds of washing units:

- Compacta: A high-efficiency open-width washing machine

SuperFlush: A high-efficiency open-width washing machine with a counter-flow system

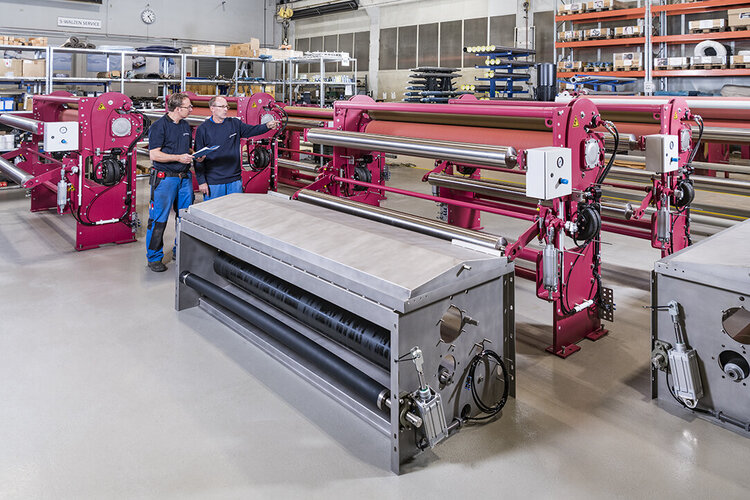

Compacta

The unique design of washers with an up-and-down continuous washing operation is highly effective. The modular construction enables it to integrate with all pre-treatment ranges.

Full-fluid-capacity washing machine

Up-and-down washers with squeezing rolls on top for improved efficiency

Closely positioned rolls for liquor penetration and avoiding creases

Direct or indirect heating (optional)

Accumulator type washer to enhance the washing effect

Removes all soluble deposits from the surface of the fabric

Fabric travels in the opposite direction to the flow of liquid

Combination of surface washing and penetration washing of all types of fabrics, heavyweight to delicate, without creasing

Diffusion of hydrolysed colours for complete washing

Even and maximum squeezing for improved efficiency

Significant savings in terms of chemicals, energy, water and time

Less polluting and more eco-friendly

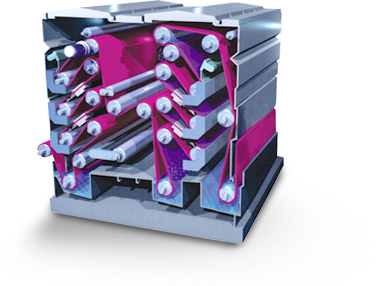

SuperFlush

This open-width tall washing machine is a combination of 'immersion', 'counter-flow' and 'penetration'. Due to this, the washing efficiency is extremely high. It consists of two vertical rows of single troughs on the fabric path for immersion, and water cascading down causing saturation while the fabric path moves in the opposite direction to the water flow. Fresh water is added from the top.

Washing efficiency independend of line speed because of additional mechanical water force

Short distances between a high number of rollers benefit penetration and avoid creasing

Little liquor content, multiple use of wash liquor due to circulation

Direct and indirect heating by external heat exchanger (optional)

Controlled drive system for process tuned fabric tension

Superior washing due to immersion, penetration and counter-flow

Reduced number of squeezing units result in a shorter washing range

Lower water consumption compared to conventional washers

Water is recycled to reduce water consumption

Crease-free fabric run

Significant savings in terms of chemicals, energy, water and time

Easy access of range due to swing-back troughs

Maintenance-free